Siloxane Removal: Key to Clean Biogas

Biogas, a valuable source of renewable energy, is produced through the anaerobic digestion of organic matter, such as sewage sludge, municipal solid waste, or agricultural residues. While biogas primarily consists of methane (CH4) and carbon dioxide (CO2), it also contains various impurities, including siloxanes, which can be detrimental to the efficient utilization of this eco-friendly fuel.

In this article, we delve into the world of biogas cleaning, with a particular focus on siloxanes—what they are, their origin, effects, and the techniques used for their removal.

What is Biogas and Why Does it Need Cleaning?

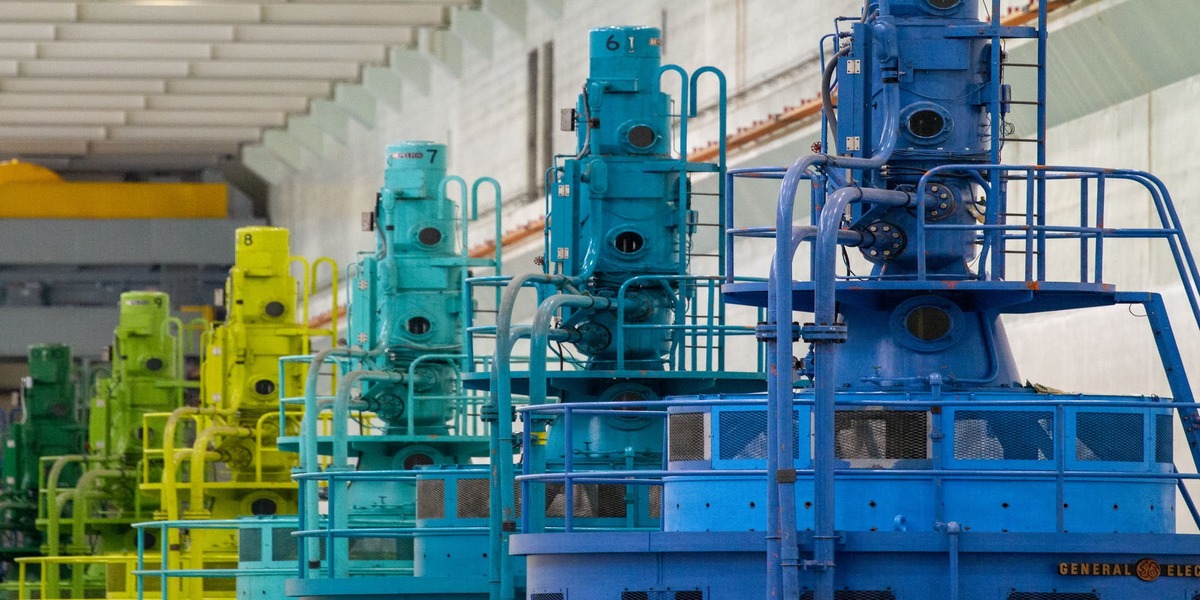

Biogas, from a technical perspective, is a gas mixture primarily composed of methane and carbon dioxide, with traces of nitrogen, oxygen, hydrogen, water vapor, siloxanes, and hydrocarbons. Though present in minuscule amounts, these trace components can significantly impact the performance of engines, turbines, boilers, and other equipment used for energy production.

Therefore, biogas is often considered a "dirty" gas and requires thorough cleaning before it can be used for energy generation or converted into products like biomethane, hydrogen, or methanol.

Types of Impurities in Biogas

Impurities in biogas can be categorized into two types: external and internal.

External Impurities

These impurities are not part of the biogas flow and must be removed as a first step. They are typically eliminated through mechanical operations like filtration or altering the dimension or direction of the biogas flow. Examples of external impurities include sediments, foams, particles, and condensates.

Internal Impurities

Internal impurities are inherent to the biogas flow and are usually removed through physical, chemical, or biological techniques. These impurities include water vapor, siloxanes, hydrocarbons, ammonia (NH3), and hydrogen sulfide (H2S). Internal impurity removal is often referred to as fine removal or polishing.

Understanding Siloxanes

Siloxanes are chemical compounds commonly used in various industrial products such as cosmetics, food additives, and cleaning agents. They are characterized by the Si–O–Si bond and can exist in different forms, including linear and cyclic siloxanes.

Siloxanes have a low boiling point, and when sewage sludge or municipal solid waste undergoes anaerobic digestion, these low-boiling-point siloxanes are released into the biogas flow.

Effects of Siloxanes in Biogas

The presence of siloxanes in biogas can lead to several issues:

Inlays on Engine Parts

Siloxanes can deposit on internal engine components, affecting their performance.

Increased Clearance

Siloxanes can increase the clearance between moving parts, leading to reduced engine efficiency.

Lubrication Issues

They may cause lubrication oil leaks or loss, affecting engine operation.

Current Techniques for Siloxane Removal

Several methods are employed for siloxane removal from biogas:

Cooling

Cooling the biogas to temperatures as low as -25°C can lead to the condensation and removal of siloxanes.

Adsorption

This involves using materials like activated carbon or silica gel to adsorb siloxanes from the biogas stream.

Washing with Reagents

Methanol can be used as a reagent to wash siloxanes from the biogas.

Combined Techniques

Some facilities employ a combination of techniques, such as drying, followed by activated carbon adsorption.

Frequently Asked Questions

1. Why is it essential to remove siloxanes from biogas?

When present in biogas, siloxanes can lead to engine and equipment damage, increased maintenance costs, and reduced energy production efficiency.

2. What are the potential effects of siloxane deposition in engines?

Siloxanes can lead to inlays on engine parts, increased clearance between moving parts, and lubrication issues, impacting engine performance.

3. How can siloxanes be removed from biogas?

Siloxanes can be removed through techniques like cooling, adsorption using materials like activated carbon, washing with reagents like methanol, or combining these methods.

4. What benefits are associated with effective siloxane removal?

Effective siloxane removal ensures optimal operation of machines using biogas, reduces maintenance costs, prolongs the useful life of activated carbon, and leads to high-quality biogas for energy production.

In conclusion, siloxane removal is a crucial step in biogas cleaning to ensure this renewable energy source's efficient and sustainable use, paving the way for cleaner energy production and reduced environmental impact.

Comments

No comments yet. Be the first to comment!