Going Digital In A GLP Environment

This article explores digital transformation in GLP-regulated companies, covering benefits, compliance, data integrity, automation, future AI/IoT trends, and key challenges with strategies for successful implementation.

For a typical GMP (Good Manufacturing Practice) based company, the data supports the product; but in a GLP (Good Laboratory Practice)-regulated study, the data is the product. This gives some GLP compliance professionals a little anxiety over making the move. In addition, the GLP regulations are fairly silent on using digital strategies and, therefore, can be wrongly interpreted as not allowing them.

However, this is not true.

Implementing Digital Technologies in GLP-Regulated Company

For a GLP-regulated company, going digital means adopting and implementing digital technologies and solutions in their operations and processes. This transition to digital systems and tools can have different implications for a GLP-regulated company.

Before jumping in and digitalizing everything, here are a few key points to consider:

Electronic Data Management

Going digital involves digitalizing and managing laboratory data and records electronically. This includes electronic data capture, storage, and retrieval of study-related information, such as raw data, study protocols, standard operating procedures (SOPs), and quality control documentation. It typically replaces traditional paper-based systems, enabling more efficient data management and reducing the risk of errors or loss of information.

Laboratory Information Management Systems (LIMS)

GLP-regulated companies can implement LIMS to streamline their laboratory workflows, data tracking, and sample management. LIMS software allows for automated data entry, sample tracking, instrument integration, and result reporting, improving overall data integrity, traceability, and compliance with GLP guidelines.

Electronic Document Management Systems (EDMS)

Digital transformation involves adopting EDMS platforms for managing and controlling documents related to GLP studies. This includes SOPs, study protocols, study reports, and other relevant documents.

EDMS ensures version control, document access control, and audit trails and facilitates stakeholder collaboration while maintaining compliance with GLP regulations.

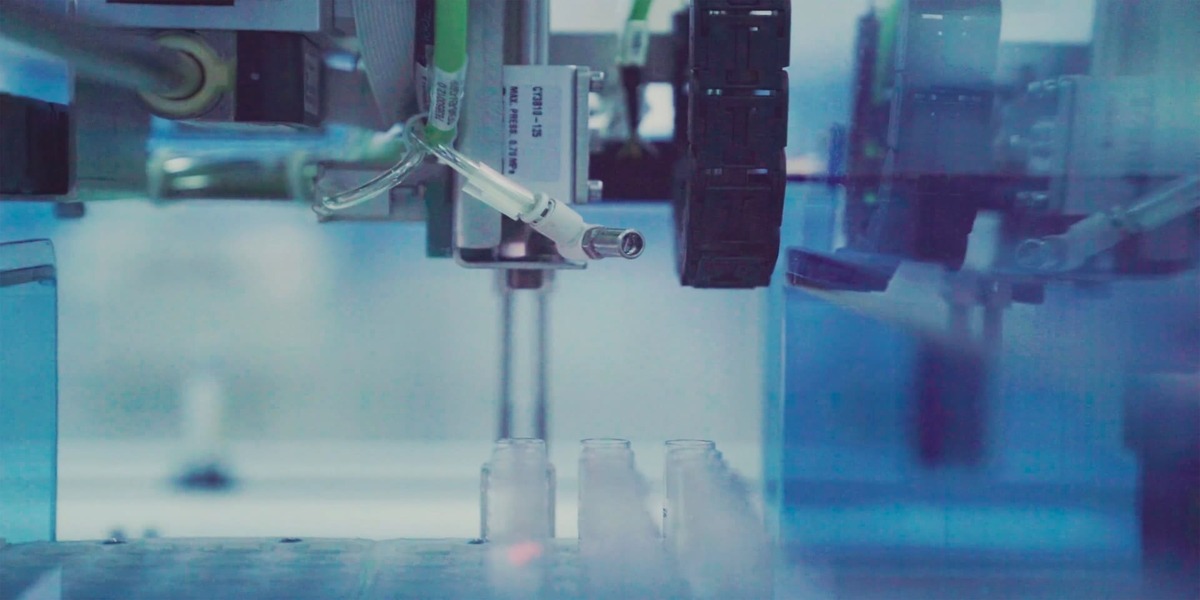

Instrument Integration and Automation

Going digital often involves integrating laboratory instruments and devices with data management systems. This integration directly transfers instrument-generated data into electronic formats, reducing manual transcription errors and improving data integrity. Automating laboratory processes, such as sample handling, data analysis, and report generation, can enhance efficiency, reproducibility, and compliance with GLP requirements.

Quality Management Systems (QMS)

Digital transformation can also impact a GLP-regulated company's QMS by enabling digital tools for managing deviations, corrective and preventive actions (CAPAs), change control, and training records. A digital QMS can enhance compliance, traceability, and efficiency in managing quality-related activities within the organization.

Data Security and Compliance

When going digital, GLP-regulated companies must ensure robust data security measures and compliance with relevant regulations, such as data integrity requirements, electronic signature regulations, and data privacy laws. Implementing appropriate data encryption, access controls, user authentication, and audit trails are essential to protect data integrity and maintain compliance with GLP guidelines.

Benefits of Digitalization of GLP-regulated Company

Going digital for a GLP-regulated company can bring significant benefits, including:

- Improved data integrity

- Enhanced efficiency

- Streamlined processes

- Better traceability

- Increased compliance with regulatory requirements.

However, it also requires careful planning, validation, and training to ensure a smooth transition while maintaining the highest standards of GLP compliance.

Frequently Asked Questions

1. How do you ensure data integrity and security when implementing digital strategies within your GLP-regulated organization?

Several strategies can be employed:

Implement Robust Data Management Systems

Creating standardized workflows that ensure data integrity, including complete, consistent, and accurate data, is essential.

Role-Based Access Control

Implement role-based access control to ensure only authorized individuals can access specific data. This method limits the data each employee can access based on their role, further securing sensitive information.

Data Verification and Validation

Regular auditing procedures should be in place to verify and validate data, ensuring it meets integrity standards.

Encryption

Use industry-standard encryption methods for data at rest and in transit to protect against unauthorized access.

Backup and Recovery Plans

Implement reliable backup strategies and disaster recovery plans to ensure data can be restored during data loss or corruption.

Employee Training

Regularly train staff members on the importance of data integrity, potential cyber threats, their role in data protection, and correct data handling within the organization.

Create a Culture of Compliance

Encourage a workspace that values data integrity, enforcing standards as part of the organizational culture.

Regular Software and System Updates

Keeping software and systems up-to-date can help protect against new security vulnerabilities. Remember, the aim is to meet GLP standards and create an environment where data integrity and security are prioritized.

2. How does the digital transformation impact the overall workflow and processes in GLP studies, and what benefits have been observed so far?

Digital transformation impacts the overall workflow and processes in GLP studies primarily by enhancing efficiency, improving data quality, and fostering better compliance.

Digital transformations include automation, reducing the need for repetitive manually recorded measures. This saves time, creates efficiency, and reduces susceptibility to errors.

In addition, data management systems facilitate data collection, storage, and analysis, reducing administrative burdens and possibilities of misinterpretation. Digital tools have improved communication and collaboration among different teams and individuals in other locations. This fosters efficient work processes and data sharing among professionals working on a study.

3. What future developments or advancements do you foresee in the context of digitalization and instrument integration within GLP-regulated environments?

There are several that could be applicable:

Artificial Intelligence (AI) and Machine Learning (ML) algorithms

They may play a significant role in GLP-regulated environments. They can automate data analysis, improve predictive modeling, and assist decision-making processes. Not only could this increase efficiency, but it could also lead to more precise and accurate results, minimizing human errors.

Shift to Cloud-based Systems for storing GLP

Data will likely continue, providing benefits like ease of access, enhanced collaboration, and robust data protection. These systems might incorporate AI capabilities to automatically analyze recorded data, detect anomalies, and propose corrective measures.

Internet of Things (IoT)

These networks could play a crucial role in the real-time monitoring of instruments and experiments. By integrating these devices, labs can increase automation and improve data collection accuracy, which are necessary for GLP compliance.

In addition, digital tools may enable real-time remote auditing and inspection, ensuring consistent adherence to GLP protocols when physical presence is not possible. Such innovations reduce disruption in lab activities and maintain safety during situations like pandemics.

These are just a few potential developments. With rapid tech advancements, there may be other unexpected innovations aiming to make GLP-regulated environments more efficient, secure, and reliable.

4. What are the challenges encountered during the digitalization and instrument integration process, and how can they be resolved?

The process of digitalization and instrument integration can face several challenges.

Lack of standardization can be a big challenge

Inconsistent processes across different locations or departments can lead to inefficiencies in digitalization. Implementing standard operational procedures and protocols can ensure uniformity.

Numerous digital tools are available

Selecting those which are the best fit for your particular business needs can be a challenge. This can be resolved by thoroughly analyzing the organization's needs and properly researching and vetting potential tools or services.

Data from various tools and systems may need to be more aligned, leading to mismatched information. This can be resolved by using standardized formats for data entry, performing regular data cleaning, and utilizing advanced data integration tools.

Change Management Issues

Finally, there may be change management issues. Employees might resist

change, especially when it comes to adopting new technologies. To help resolve this, employers can provide comprehensive training, promote an open culture to address concerns, and ensure everyone understands digitalization's benefits.

Comments

No comments yet. Be the first to comment!