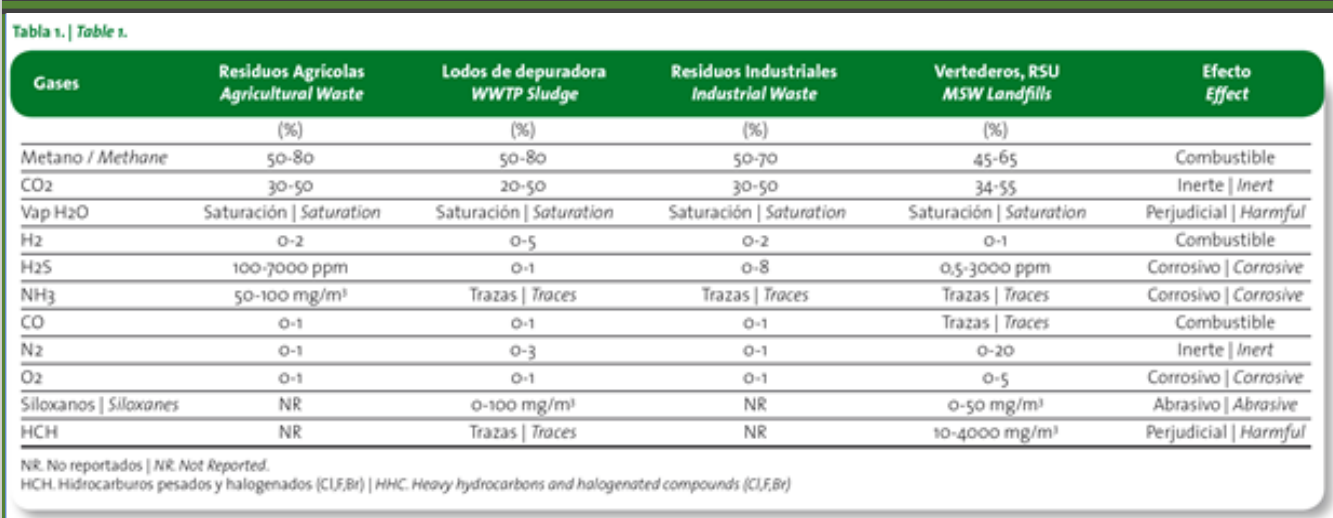

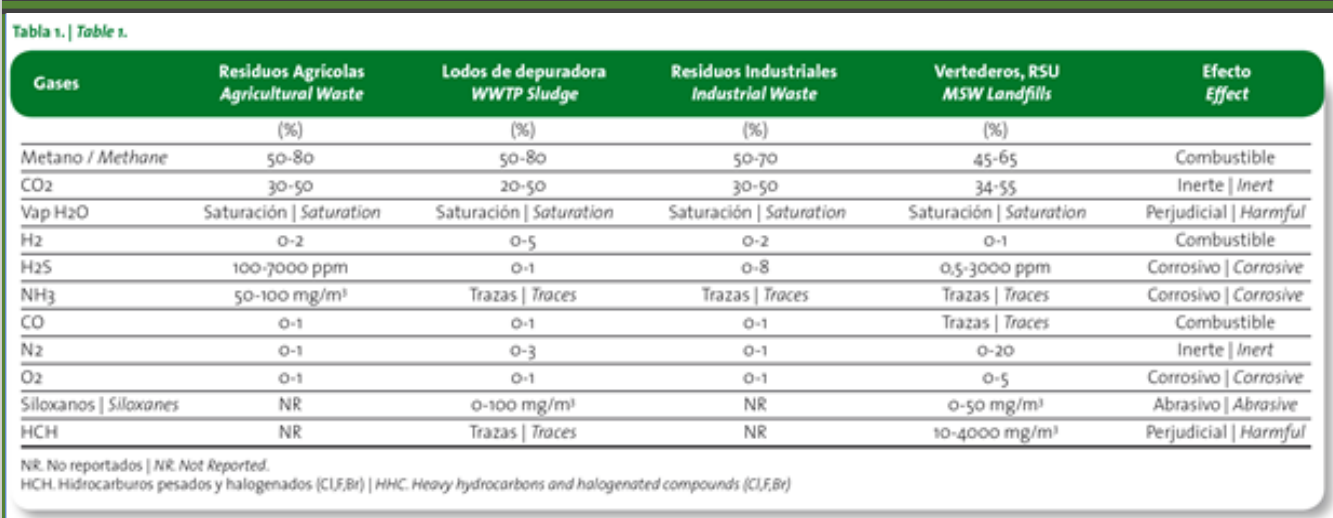

Biogas is a promising renewable energy source, primarily composed of methane, carbon dioxide, nitrogen, oxygen, and trace impurities such as hydrogen sulfide (H2S), siloxanes, hydrocarbons, and water vapor. To utilize biogas effectively as a raw material for energy production or other products like biomethane, it must undergo a thorough cleaning process to remove harmful impurities.

BTS-MPdry is an innovative technology that offers an efficient way to clean biogas, resulting in numerous benefits for the biogas industry.

Biogas Cleaning

Biogas can be derived from uncontrolled processes, such as landfills or lakes, or controlled processes, like wastewater treatment plants (WWTPs). Irrespective of its origin, biogas is considered a "dirty gas" due to the presence of external and internal impurities that must be eliminated for optimal use.

BTS-MPdry: An Innovative Biogas Cleaning Technology

BTS-MPdry is a cutting-edge biogas cleaning system that effectively removes both external and internal impurities, ensuring the high-quality utilization of biogas. The cleaning process involves:

- Desulfurization (H2S removal)

- Biogas drying (water vapor removal)

- Biogas polishing using activated carbon filters

Case of Study: Alcala Oeste WWTP, Madrid, Spain

The BTS-MPdry technology was implemented at the Alcala Oeste WWTP in Madrid, Spain, with impressive results. The system demonstrated exceptional performance in removing impurities, leading to higher biogas quality, reduced maintenance costs, and improved exhaust gas emissions. The study indicated substantial cost savings and enhanced profitability for the CHP system.

Conclusion

BTS-MPdry presents a game-changing solution for the biogas industry by effectively cleaning biogas, removing harmful impurities, and promoting sustainable and efficient energy production. This technology optimizes the operation of biogas-based machinery and contributes to a greener environment through reduced emissions.

Cleaning biogas with BTS-MPdry opens new possibilities for harnessing biogas as a reliable and clean energy source.

Frequently Asked Questions

1. What are the main impurities found in biogas, and why are they harmful?

The main impurities in biogas include water vapor, hydrocarbons, hydrogen sulfide, and siloxanes. They can reduce energy content, cause corrosion and engine damage, and emit harmful gases.

2. How do these impurities affect the biogas utilization process?

Impurities decrease energy production efficiency, increase maintenance needs, and lead to harmful exhaust gas emissions, affecting CHP system performance.

3. What are the consequences of not removing these impurities from biogas?

Failure to clean biogas can lead to decreased energy efficiency, frequent maintenance, increased emissions, and reduced profitability of CHP systems.

4. What benefits can be achieved through effective biogas cleaning?

Efficient biogas cleaning results in optimal machinery operation, reduced maintenance costs, prolonged equipment life, improved emissions compliance, and enhanced personnel safety.

Create an account to read the full article

Create Account

Already have an account? Sign in